There are two methods to display print with a squeegee, either push or pull the squeegee. Pulling the squeegee toward you is the traditional methodology, however I often push the squeegee when manually display screen printing for lengthy intervals of time. For best squeegee upkeep, a squeegee ought to all the time be wiped clean and dry following its elimination from the press and stored flat in a dry surroundings at room temperature. The blade must be allowed to get well from the ink and solvent attack and relaxation for twenty-four hours.

Made of gold-tone aluminum, with a medium-soft purple blade, it ... Provides more protection than 70 duro and is nice for discharge printing. This 12 squeegee rack adds a lot wanted organization and cleanliness to any shop. This 8 squeegee rack adds much wanted group and cleanliness to any shop. This 4 squeegee rack adds a lot needed group and cleanliness to any shop. 90 Duro squeegees are the stiffest out there and are great for more intricate print jobs.

The Speedball Graphic Squeegee is designed for graphic display printing however may also be used on paper, cardboard, or wood. Fimor's Polyurethane Formula is undoubtedly one of the best squeegee blade out there in our business. The silk screen printing exact control of durometer hardness is unsupassed and insures repeated accuracy in all the blades they produce. The SR-1 series presents a range of single-durometer and triple-durometer choices to greatest fit your application. Lawson also offers squeegee clean up and auxiliary objects like squeegee playing cards, the Ultimate Ink Cleaning Card and squeegee racks for great storage.

This can be helpful if you have been printing white on a black t-shirt, and you can not get it too covered with the more durable squeegee. By sustaining your squeegees you’ll keep the crispness and quality of your display screen prints, and you’ll ultimately save your store money on each alternative squeegee blades and ink. Because the moisture in ink causes squeegee blades to swell and soften throughout use, it’s essential to limit your use of each individual squeegee. It’s recommended that you just change out your squeegee after 4 to 6 hours of printing, or a day of printing if it’s a decrease production day. Have a rotating supply of squeegees so every squeegee can rest for twenty-four to forty eight hours between every use.

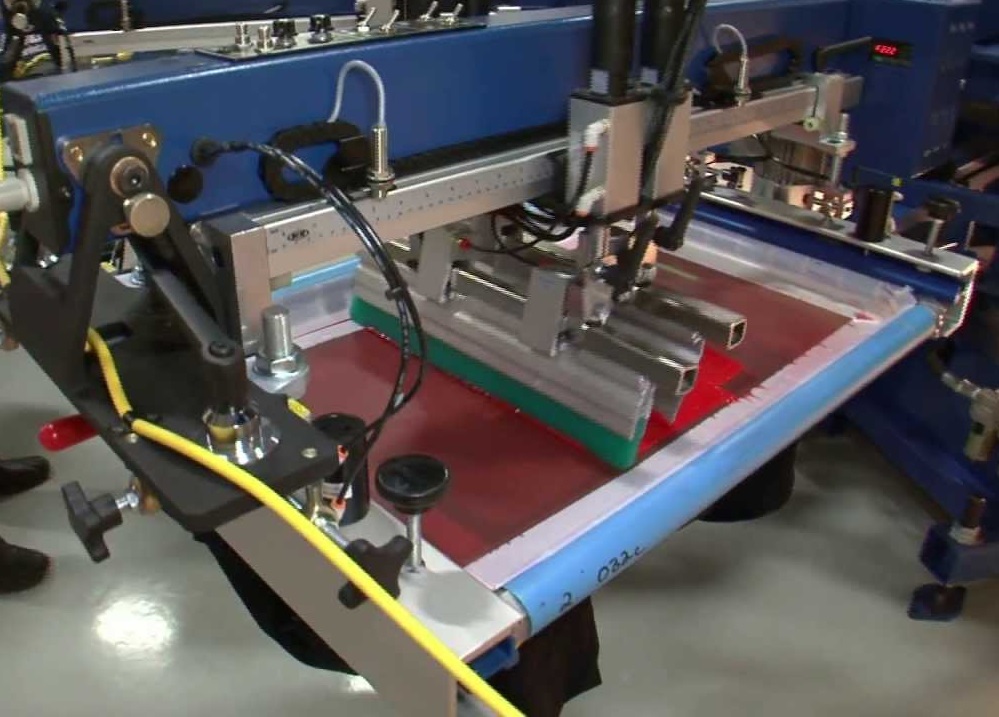

60 Duro squeegees are very soft and lay down essentially the most ink. Aluminum winged floodbars for Workhorse and M&R automated presses. Squeegees and floodbars can be found in a variety of sizes for all MHM Screen Printing Machines.